Garment Production

- Isobel Millington

- Oct 8, 2020

- 53 min read

Updated: Jan 13, 2021

Continuing with the project 'print, pattern, colour' I am going to learn methods in pattern cutting and garment production through a series of practical lessons. This will allow me to develop and build my fashion skill base, opening up to methods and cuts that I may wish to use during this course. I will also parctice sampling out samples on the sewing mchine, practicing out processes that would be used in garment production, such as seems and hems.

I first started sampling out different seams, darts, hems, button holes and pleats on the sewing machine to practice for garment production. Many of these techniques consist of processes which help to produce garments which I went through to create finished samples.

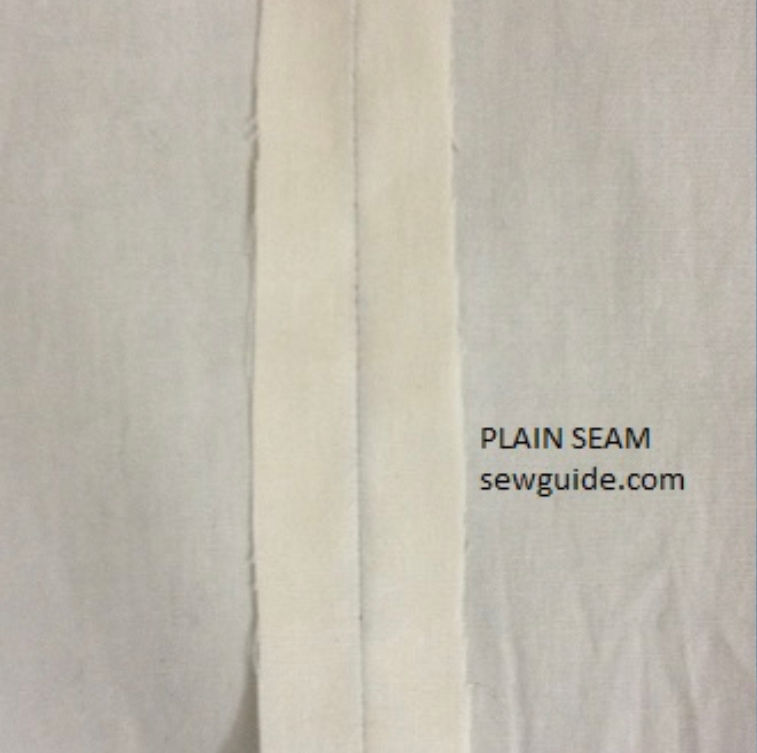

Basic Seam

I first started of with sampling out a basic seam. A basic seam is used to close the bias tape around a raw edges, or for a garment to be sewn inside out with lining, to then be pulled through to the correct side having clean finished turned in edges. The process of this seam is putting wrong sided fabric pieces together, and then sewing a straight line down the side. This creates a basic seem.

French Seam

I then created a sample of a French seam. The construction of the French seam provides a clean, finished, professional look to the inside of a garment. This process started similarly to a basic seam, however after you created the basic seam you would turn the material to the other side, folding the material over and then sewing along the seem that is underneath. French seams are often used when the fabric is too delicate to overcast the seam allowance to prevent revealing.

Hems

I then experimented by sampling out a double folded hem. A hem is a garment finishing method, where the edge of a piece of cloth is folded narrowly and sewn to prevent unravelling of the fabric. For this process I folded the edge of fabric in twice then sewed it down.

Darts

I then went onto sampled out darts. Darts are folds (tucks coming to a point) and sewn into the fabric to take ease and provide shape to a garment. Darts are most commonly used in women's clothing due to women having more curvy siloheots and larger bust. They are used in all types of clothing to tailor the garment to the wears shape. For this process I drew out my dart and sewed it in on my fabric.

Pleats

I then went onto experimenting with pleats and practicing this technique out on the sewing machine. Pleats are commonly used in clothing and upholstery to gather a wide piece of fabric to a narrower circumference. Pleats are categorised as pressed. This means ironed or heat set into a sharp crease,

or unpressed, falling in soft rounded folds. Pleats sewn into place are called tucks. For this process I pinned in my pleats and sewed 1cm away from the top of the edge. I then ironed my pleats in place to fix in the position of the pleats.

Button Holes

I then finally tested out making button holes and practiced using the button hole machine foot. Button holes are reinforced holes in the fabric that buttons pass through, allowing one piece of fabric to be secured to another.

The raw edges of the button holes are usually finished with stitching. This may be done either by hand or by a sewing machine. I practiced this process using a sewing machine. For this process I had to put the sewing machine in the correct settings and made sure the button hole foot was fitted nicely before I started sampling out button holes. I practiced sewing a variety of button holes before I was satisfied with the results.

Pencil skirt garment making sample

Cutting out the pencil skirt patterns from the fabric

To start of practicing garment making I made a basic zip pencil skirt. This was a sampled garment piece of production so that I could practice putting this garment together, learning the specific techniques required while making it. To start of by making this pencil skirt, I layed out the skirt paper patterns onto my chosen material which was red tartan cotton fabric.

Before I pinned my patterns down onto my material, I first folded my material for one of my patterns because it was a pattern that had to be placed on a fold line so when I cut it I'm only cutting around the three three sides. The other pattern was a reverse pattern where I would cut around it one side then turn it the other side and cut around it that side. To save time I cut around this pattern with my material folded and cut around all four sides. The patterns I had included darts, therefore I wanted to make sure I pinned the darts down securely onto my red tartan fabric and so that I could cut around them neatly.

I wanted to cut around the patterns neatly and precisely so my pencil skirt could be constructed and sewn together accurately. However I found it hard cutting around the pattern as it was hard to guide the scissors down in a straight line. For future reference I will mark around the patterns using tailors chalk. This will mean I can cut out my patterns and darts more neatly and precisely.

Marking out and sewing in the darts

Once I had finished cutting out all my patterns I started sewing in the darts. I firstily measured how long the dart was in cm from the pattern template, then I marked this out onto my fabric darts. The dart was 16 cm long so I folded my fabric darts in, lining them up neatly, and used a ruler to mark out the darts in tailors chalk. I then pinned down the folded darts precisely folding them accurately, so they would be fixed and secured when I sewed them in.

While sewing in my darts for the pencil skirt, I made sure I was slow and controlled on the sewing machine to get accurate straight sewn in darts. I wanted all of my darts to match so that my pencil skirt could be made as professional as possible.

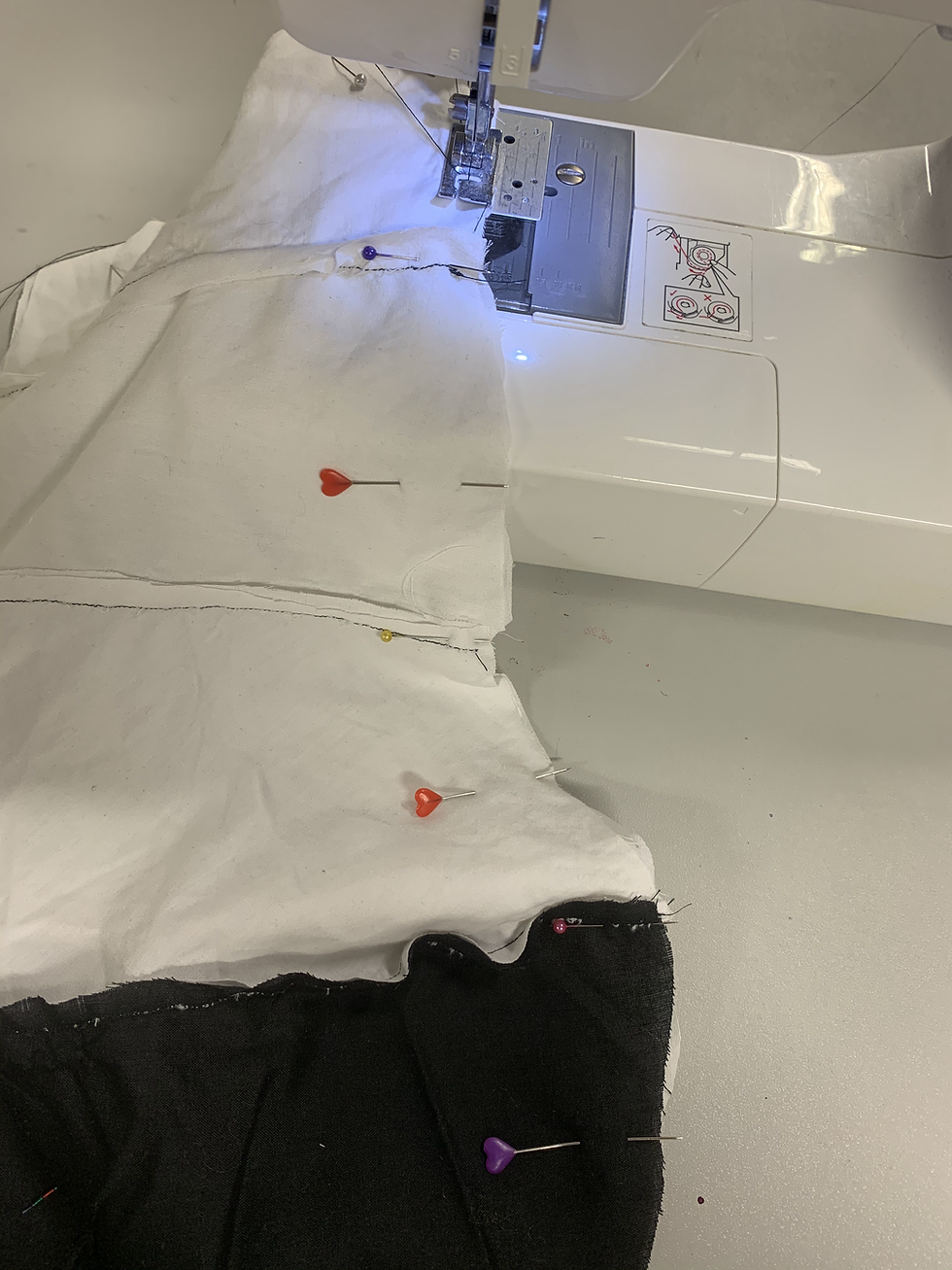

Sewing and pinning the two back panels to the front panel

After I had sewn in my darts on my pencil skirt I then went on to pinning and sewing the two back panels to the front panel. To do this I placed down my front panel piece of fabric (right side up). I then placed my two back panels of fabric on top of it so that it was right sides together.

I then pinned the two sides in place lining them up neatly to the sides of the front panel of fabric. I then sewed down the sides using the basic seam technique.

While sewing the two back panels to the front panel I made sure I went at a slow pace on the sewing machine to get a clean accurate line down, making sure I had the correct amount of seam allowance. I had a seam allowance of approximately 1cm to get a neat basic seam.

Sewing in the Zip

To begin sewing in the zip I first placed the zip at the top and down the edges of the two back panels that meet. I then marked out where the end of the zip reaches so I could then sew the two back panels together up to the certain point I marked out. You do this process to mark out where your zip lies so that it fits and slots in neatly when you sew it in place. I then folded the sides of the two back panels in onto the zip while pinning the zip in place. This was to get neat clean edges that wouldn't fray along the zip. Once the zip had been sewn in place I then opened it up to sew down each side, as this process made it more easy to get a neat straight stitch down the zip.

During this process I made sure I took my time sewing in the zip because the stitches will be on the front and on show. Therefore, I wanted to make sure I made it extremely neat and accurate.

Sewing in the hem

To sew in the hem line I folded the edge of the skirt in twice and ironed it in place so that it would be fixed in its position and easier for me to sew over.

I then pinned down the double folded hem in place pinning it horizontally so that when I come to sewing the hem In I can sew over the pins. I folded the double hem in so the it was folded the inside out side of the skirt. Once I had pinned the hem in place I examined the hem to see if it was evenly folded over and pinned. I then eventually moved onto sewing in the hem making sure I was as close to the edge of the hem as possible.

While sewing in the double hem line I wanted to stay slow and controlled on the sewing machine because the stitch will be on show and I wanted to make it as neat as possible.

Making and sewing in bias bonding

For the waist line of the pencil skirt I made bias bonding out of my tartan red fabric. To make the bias bonding, I cut out a long strip which would be made into the waist line of my pencil skirt. Once I had cut out this long strip, I folded the two sides of the strip in and ironed this in place. This was to make the bias bonding stay fixed in place when sewing it into the waist line. It also makes it much more easy to pin it accurately and evenly around the waist line.

After ironing the bias bonding I pinned one side in place onto my pencil skirt (inside out) with the bias bonding facing with the folded in folds at the front. I folded in the front edges of the bias bonding to make it neat so that it would have a professional finish. I then sewed this one side on to my pencil skirt making sure I was steady and controlled on the sewing machine. However this stitching wouldn't be seen as I was sewing it right sides together (front panel and back panel of the skirt to the front of the bias bonding) so I made a basic seam. After I had stitched the one side of the bias bonding, I then went onto stitching in the other side. This side was stitched in on the front so the stitching would be seen. Therefore, I made sure I was specifically slow and controlled on the sewing machine so I achieved a neat straight stitch. Before I stitched this side of the bias bonding in I made sure it was securely pinned in place and looked equal in size all around the waist line. After stitching in this side of bias bonding I then neatly had to sew the waist line up to the zip. After doing this process my pencil skirt was finished and complete and I then evaluated the stitching and techniques, deciding what I did well on and what I could improve on In the future.

One of the things I thought I could improve on in the future was sewing the bias bonding waist line closer to the zip, so that it fit in more neatly and accurately. Another thing I noticed I could improve on in the future was the stitching around the bias bonding. The stitching was overall neat and straight around the waist line, however there was a slight bump from when I stitched over one of the darts. For future reference I will specifically sew slow and controlled when sewing over the darts to prevent getting an uneven stitch line. After evaluating the features on my skirt I thought I could improve on, I then evaluated the elements I liked. This was the neat precise hem line and the accurate symmetrical darts. I was extremely proud of my hem line on the pencil skirt as it was evenly folded and stitched the whole way round. I was also pleased with my darts as I felt they were extremely even and accurate. I then revisited my skirt and unpicked the bias bonding on the waist by the zip so that I could sew and fold in the bias bonding by the zip more accurately and precisely.

Here is my improved version of the pencil skirt with the waist line bias bonding and the zip. Overall I am extremely pleased with how my improved attempt worked out because it looks a lot more neat, practical and presentable. After making my improvements I evaluated the pencil skirt again. For my first attempt at making a pencil skirt I was extreemly proud of how it turned out because the pencil skirt was presentable for the human eye and practical to wear.

The finished garment - the pencil skirt

My finished pencil skirt looked beautifully appealing to the human eye creating, an elegant and classy look. When capturing my pencil skirt I pared it with a gorgeous white blouse so that the patterned red tartan fabric could thoroughly stand out and appeal. This would create a fabulously unique item of fashion for formal clothing, which would create a stylish and smart look. The target market for the pencil skirt I created is aiming for the age bracket between 18-30 years of age. This garment fits this target market specifically as it presents a young style of clothing that is formal but also stylish, with the touches of red on the gorgeous tartan fabric. The addition of colour creates a more funky style of formal clothing, which would make a unique office style look and a unique style to other formal jobs. It also presents a gorgeous addition for smart casual clothing a swell which would make a Devine winter style look because of the touches of red on the tartan skirt.

Boxy T-Shirt garment sampling

To practice sampling another garment I made a boxy T-shirt learning what patterns are used to form the boxy T-Shirt and the process of putting them together using the differnet techniques.

Cutting out the paper patterns and placing them onto my chosen fabric

Firstly I started by cutting out the paper patterns and placing them in certain way on my chosen white cotton fabric. Further more, on two of my patterns i had to cut them on a fold which meant i had to fold my material and pin the two patterns along the fold line. One of the patterns was a reverse pattern which meant you would pin it onto the fabric and cut around it one side, then do the same again but facing the pattern the other way round and pinning and cutting around it from that side.

When doing this process I made sure that I placed the paper patterns onto my chosen material appropriately so that I could save as much fabric as possible. During this process I cut out the patterns delicately from my material so that I could achieve neat cut out fabric pattern pieces. This would make it easy for the individual pattern pieces to be pinned and sewn together.

Sewing the front of T-Shirt to the back of T-Shirt

To begin putting the patterns together I pinned the back panel of the T-Shirt to the front panel of the T-Shit pinning at the top two horizontal edges, and the two vertical edges on the sides, missing out the neckline and the open bottom of the T-Shirt.

When I pinned the back of the shirt to the front, I pinned them right sides together so that when I turn it the right way the seams will be hidden, neat and clean. Once I had pinned the back panel of the T-shirt to the front panel of the T-Shirt I then went onto sewing and securing them together on the sewing machine.

When sewing the back panel of the T-Shirt to the front panel of the T-Shirt I made sure that I was slow and controlled on the sewing machine, so that I got a straight neat seam. I chose to sew in white thread so that it matched the colour of my white cotton fabric, and will be harder to see. I was over all happy with the stitching of my basic seems when stitching these two panels (front and back) together.

Sewing the sleeves and sewing them onto the T-Shirt

To begin constructing the T-Shirts sleeves I fist folded both sleeves (right sides together) and pinned and secured the two open folded edges in place. I then stitched down this horizontal edge of both of the sleeves making sure I was steady and controlled on the sewing machine to get a straight neat basic seam. After I had stitched both of the edges of the sleeves I moved onto securing the sleeves onto the T-Shirt. To do this I turned the T-Shirt inside out and and pulled the sleeves through the shirt. facing the right way through. I then pinned them around the arm holes. I matched up the arm hole T-Shirt seems to the sleeve seems, fixing them in place then finished pinning around the sleeves securing them to the T-Shirt. I pinned the sleeves onto the T-Shirt in a specific way so that I could sew over them on the sewing machine. This method makes it much more easy and fast on the sewing machine.

To sew in the sleeves on the sewing machine I had to take off the removable bottom compartment so that I could slide the sleeve through onto the sewing machine. This makes it much more manageable to sew around the sleeve in a neat line and makes it more easy to guide the sleeve around when sewing.

I wanted to be extremely slow and controlled on the sewing machine when sewing in the sleeves so that my sleeves were neat and both of the seems (the sleeve seem and the T-Shirt seem) matched up perfectly.I also wanted to stay slow and controlled on the sewing machine so I could guide the sleeve through gently without it getting caught. When sewing in the sleeves I used white thread to match the white cotton material I had chosen so that it would be less easily seen.

Sewing in the hems

Once I had stitched the sleeves onto the T-Shirt I then went onto hemming the bottom of the T-Shirt and the sleeves. I first started with hemming the bottom of the T-Shirt using the double hem technique. The process of this hem is folding it in twice and pinning and stitching it in place.

When I double hemmed the bottom of the T-Shirt I made sure that the hem was equally folded all around before I pinned and secured it in place. I then moved onto stitching the hem in place on the sewing machine, stitching as close to the edge of the hem as possible. To make stitching the hem in place easier on the sewing machine, I removed the removable compartment and pulled The bottom of the T-Shirt through. This helped guide the sewing machine around the hem more easily. I made sure I gently guided the sewing machine around the hem so that it wouldn't get caught underneath. By doing this process the hem will be much more accurate and neat. I then moved onto hemming the T-Shirts sleeves doing the same technique folding it in twice then pinning and sewing it in place. I stitched the hem lines in using a cream tinted colour thread to create a subtle pretty outline. After the hems had been sewn in I then ironed and fixed them in place.

Over all I was proud of my hem lines because they were accurate and equal the hole way round. In addition to this the stitching was straight and consistent throughout. While stitching the hems in place on the sewing machine, I made sure I was slow and controlled so that I could achieve a consistent straight stitch all the way around the hem line.

Making the bias bonding for the neckline and stitching it in place

To make the bias bonding for the neckline of the boxy T-Shirt I had to cut out the a strip of my white cotton fabric. The bias part of a material is diagonal and is the most ease, stretching part. The bias bonding for the neckline had to be cut out diagonally so that it easily stretched around the curved neckline edge. I cut the bias bonding strip with a 10cm width and a length that I thought would be enough to cover around the whole neckline. This was about 60cm. After I cut out the strip from the diagonal bias line for my bias bonding, I then folded in both sides and ironed them in place. This process is done so it is more easily pinned and sewed into the neckline.

Once I had finished ironing in the two folded sides, I then pinned and secured the one ironed side of the bias bonding around the neckline, easing and pulling to stretch around the curved neckline. I made sure I stared from the middle at the back of the T-Shirt and pinned around. I pinned the bias bonding inside the t-shirt first with the folded in flaps facing the front. For the ends of the bias bonding I folded and pinned them in so that I could achieve a neat tucked in end. After I had pinned the one side of the ironed bias bonding, I then sewed and secured it in on the sewing machine. I then folded over the other ironed side of the bias bonding to the front of the T-Shirt and pinned it in place. I made sure that the bias bonding was equally folded all the way round the neckline. When sewing this part of the bias bonding in I made sure I was extremely slow and controlled on the sewing machine, because this part of the stitching would be on show. I specifically chose to stitch this part in by using white cotton thread so that it matched my white cotton material and would be less noticeable. When I came to the folded in ends of the bias bonding at the back of the T-Shirt I made sure they were sewn in neatly and tucked in.

Over all I was pleased with how my boxy T-Shirt turned out. The hem lines were extremely neat and professional. In addition to this the sleeves were made acurrately with both of the seams meeting. However improvements for future reference would be the neckline (bias Bonding) of the boxy T-Shirt. I was not happy with how the neckline (Bias Bonding) turned out as the stitch control wasn't consistent and precise. I also didn't stitch around the neckline (Bias Bonding) as close to the edge as possible. This caused the neckline (Bias Bonding) to fold up and look uneven. Therefore, in future I will be more slow and controlled on the sewing machine to achieve an elegant professional look.

Improvements I made to the Boxy T-Shirt

To improve my Boxy T-Shirt I wanted to improve the neckline area. I decided to revisited the neckline area and redo it using red tartan fabric, the fabric fabric I used to make my pencil skirt. By adding a touch of coloured pattern material I feel that it will Britern up my boxy T-Shirt making it stand out with uniqueness and elegance. This would create a fabulous item of fashion. First I cut out a strip of my tartan fabric along the bias diagonal line. I made the width of the bias bonding slightly thicker this time so that the neckline was bold and the tartan fabric could stand out.

Once I had cut out the bias bonding along the bias line on the fabric, I folded the two sides in along the strip and ironed them in place. Once I had ironed then in place, I pinned the one ironed side of the bias bonding around the neckline making sure I folded in the ends at the back of the T-Shirt, so that it was tucked in and neat. Once the one side of the bias bonding had been pinned in place, I then sewed and secured it in on the sewing machine. I then folded over the bias bonding and pinned it onto the front of the boxy T-Shirt. Once I had pinned it in place I sewed it in on the sewing machine making sure I was extremely slow and controlled. This is because this stitching would be shown, therefore I wanted to make it extremely accurate and precise. To sew in the tartan neckline I used white thread as I felt the contrast of red and white complimented each other nicely.

Over all I was really pleased with how the tartan neckline turned out. The stitching was extremely controlled and consistent around the whole neckline. The end of the bias bonding on the neckline was neatly hidden and tucked away. The contrast of the white cotton fabric and the red tartan fabric complimented each other positively, Which created an autumn/winter item of fashion.

The decorative frills

To make my boxy T-Shirt elegantly appealing to a viewers eye, I designed gathered frills that that drooped over the shoulders and down to the bust. To make these frills I first cut them out in white cotton fabric. I did this with the white cotton fabric folded so that when I cut out the shapes of the two frills, I had two pieces to one frill to sew together to make it more stern and stiff.

Once I had cut out all the pieces I pinned the the two pieces from each frill together. I then sewed round the curved side of the frill and the two small sides. I made sure I was slow and controlled when I did this on the sewing machine to achieve a neat basic seams. Once I had stitched the two frills on the sewing machine I turned them both the right way around to reveal the neat side of the basic seems. I then hand sewed the straight edge of the frills making a loose running stitch. When I got to the end of the frill I gently pulled the thread and gradually gathered the material to reveal a classy elegant frill. After I had gathered together both of my frills, I pinned them In place on my boxy T-Shirt. I pinned the larger side of the frill onto the top of the T-Shirt. This was on the shoulder seem. I then pinned the bottom of the frill near the bust area. When pinning the frills in place, I pinned them facing the other way so that when they are sewn in place I could fold them back over to reveal a neat frill. This method hides the stitching of the sewn in frills.

Once I had finished sewing in the frills I evaluated my finished improved Boxy T-Shirt. Overall I was drastically pleased with the new improved finished garment I had created. The frills added additional beauty and elegance and fit nicely along with the red tartan neckline. My finished Boxy T-Shirt created a fabulous winter/autumn look which made a beautiful co-ord with my red tartan pencil skirt. This garment would create a fabulously unique item in fashion and achieves a wonderful winter co-ord look.

Waterfall jacket garment sample

I practised by putting together and constructing a waterfall jacket to learn the processes and method of composing this garment. I learnt what patterns are used for this specific jacket, and how to cut them out using a certain instructed method, then sewing the cut out fabric patterns together.

Cutting out the paper patterns and cutting them from the my chosen fabrics

To make the waterfall jacket you need to have two different pieces of material (one for the outside of the jacket and one for the lining). I selected a plain black cotton fabric for the outside of my jacket and a white coloured cotton fabric for the lining. I felt these two colours would compliment each other nicely and would create a unique waterfall jacket. I first lay out my selected fabrics and pinned down the patterns in an instructed way. To explain this further, I pinned down one of the patterns on a fold line. This is because the pattern cut out had to be pinned and cut out like this specifically. This pattern created the back of the waterfall jacket, so when it was cut out on the fold line, it opened up to make a large pattern piece of fabric. Other patterns that had to be pinned and cut using an instructed method were the patterns of the sleeves and the sides of the jacket. These patterns had to be cut in reverse. This means the patterns will be pinned and cut around one side, then placed facing down and pinned and cut around the that side. After I cut out the patterns from the black material (the jackets front material), I then cut out the patterns for the lining (the white cotton material) repeating the same process with how I cut the patterns out for the front of the jacket. When cutting out the the paper patterns out of my chosen fabrics, I wanted to place the patterns out appropriately on the material to save as much fabric as possible.

I wanted to make sure I thoroughly pinned down the patterns onto my chosen fabrics so it was more easy to cut around them. I also made sure I cut around the patterns neatly to get the most accurate cut outs so it would be more easy pinning and sewing them together. I tried to lay my patterns out in a appropriate way so that I wouldn't be waisting fabric. I was extremely happy with how I cut out the patterns by trying to save my materials. However for future reference I will cut out my patterns more neatly so that the cut outs of fabric are more precise and easy to pin and sew together. To help my patterns be cut out more precisely, I will in future pin the pattern down and draw round it in tailors chalk, then cut them out. By doing this additional method it will make my patterns more accurate and precise.

Sewing the two side fronts of the jacket to the back of the jacket

Once I had cut out all the patterns from the fabric for the front of the jacket, and from the fabric for the lining I then went onto constructing the jacket together. I first pinned down the two sides of the jacket to the back piece of the jacket and sewed this in place. I pinned the top sides of the jacket to the back of the jacket and sewed this in place. I then pinned the two sides of the jacket to the back sides of the jacket, sewing them in place and missing out the arm holes. When pinning the two front panels to the back panel of the jacket I made sure I matched the two materials up neatly, before securing and pinning in place. I chose to stitch this in black thread so that the stitching would be less likely seen on the black cotton fabric, and my jacket could be as neat and professional as possible. I then repeated this processes with the lining. To create neat lining I stitched using white thread so that it matched my white cotton lining. This was so that the stitching will be less likely seen and look more neat and professional to a viewers eye.

I made sure I was slow and controlled on the sewing machine so that I had a neat basic seam. By using black thread on the sewing machine it allows the stitching to be seen more neatly as it blends in with my chosen black cotton fabric. In addition to this by using white thread for the lining it also provides a neat outcome and looks professional. Over all I was pleased with how this construction of the jacket turned out. The basic seams I stitched in place were neat and consistent all the way round, making my waterfall jacket more acutely presentable and precise.

Sewing the sleeves together and sewing them into the jacket

To sew the jacket sleeves, I folded them in so both sides met each other (right sides together). I then pinned and sewed this in place. I made sure I was slow and controlled on the sewing machine so that I had a neat basic seam and the sleeve of my jacket could be as neat and professional as possible. I also stitched the sleeves using a black thread on my black cotton fabric so that the stitching would be less likely seen. I repeated this process with the sleeves of my lining. However instead of using black thread I used white thread because my lining was a white coloured fabric.

Therefore, the stitching would be less likely seen. After I had sewn the sides of the sleeves for the outside of my jacket and the lining, I then went onto sewing the sleeves into the jacket. To do this I took the sleeves (the black cotton sleeves used for the front of the jacket) and pulled them through the arm holes. I made sure that the front of the jacket was turned inside out and the sleeves were the right way so the seams were on the neat side, when I pulled them through the arm holes. I matched up both of the seams from the arm hole and the sleeve and pinned and secured this in place. I first pinned the two basic seams together and then pinned up to half way on both sides of the arm hole. I had lots of access material that wouldn't fit and ease neatly around the arm hole. Therefore, I pleated the access material at the top of the arm hole. After both of the sleeves were pinned and pleated in place, I then stitched and secured in both of the sleeves. I used black thread again because these were the sleeves for the front of the black cotton jacket. I then repeated this process with the lining. However instead of using black thread, I used white thread to match the colour of the lining I selected.

When stitching in the sleeves for my waterfall jacket I made sure I was slow and controlled on the sewing machine, because I wanted to make the jacket as accurate and professional as possible. I went extremely slow over the pleats when sewing in the sleeves so that I could get it as neat as possible creating a unique presentable jacket. Over all I was proud how this turned out because the pleats were evenly consistent on both shoulders of the sleeves, and the sleeves were extremely neatly stitched in. For future reference I will make sure I pin the sleeve in the right way because for one of my sleeves I stitched it in the jacket inside out. However I improved this sleeve by unpicking it and redoing it again to make an improved version.

Sewing in the lining

To sew in the lining I put the front of my jacket facing the right way and the lining facing the wrong way inside of the front of the jacket. I then pinned along the top of the jacket and down the two sides. I made sure when I was pinning along the top of the jacket I lined up the lining seams to the front side of the jacket seams. By doing this it allows my jacket to be more accurately put together and neat. After I had pinned this all in place I then secured and sewed it down on the sewing machine. I made sure that I was slow and controlled on the sewing machine to exceed a constant straight outline. After I had stitched this in place I then pulled my jacket through to the right side and pulled down my lining sleeves through the front of my jacket sleeves.

When stitching the lining in place I used black thread as I thought this would be the most appropriate colour to use. This is because the colour of the front of my jacket is black therefor the stitching would be very hidden on the outside of the jacket. However the stitching may be seen more easily for the lining of the jacket because the lining is white. I decided to use the black thread to stitch the lining in because the lining will be less likely seen than the front of my jacket, therefore the black stitching in the lining will be hidden. Over all I was proud with how I stitched the lining in because I matched up the seams to make my jacket more accurate and professional. However for future improvements I will be more slow and steady on the sewing machine when sewing over the seams. This is so that I can achieve a more consistently straight stitch.

Hemming in the bottom of the jacket and using bias bonding on the sleeves

Once the lining had been sewn into my jacket I then went onto hemming the bottom of the jacket, to create a neat final garment. To hem the bottom of the jacket, I folded the two open fabrics in and pinned this in place. While pinning this in place I made sure I lined up the seams of the lining and the front of the jacket. I did this because it helps to create an accurate professional jacket with a neat hemmed line at the bottom edge.

Once I had pinned the hem in place, lining it up with the seams, I then sewed and secured this in place using black thread. I used black thread so it would be less likely seen on the outside of the black cotton jacket. After I had hemmed the bottom of the jacket, I then created bias bonding for the sleeves because I wanted to create red tartan sleeves to create a unique style of jacket. To make the bias bonding I cut out strips from red tartan fabric. I decided to cut the strips out with a width of 5cm and a length of 20cm as I thought this was the sensible amount to make a sleeve. After I had cut the two strips out I then went onto ironing them on the ironing board to create bias bonding. To make bias bonding you fold in the two sides by 1cm and iron this in place. I made sure I thoroughly ironed my strips of bias bonding so that it was stiff. This means it will be more easy to work with when creating the bias bonding for the sleeves. After I had ironed the bias bonding in place I then moved onto securing it onto the sleeves .When I secured it onto the sleeves I folded in the two ends to achieve a neat finished end. I also pinned It in place from the inner side of the sleeve with the bias bonding facing the folded was up. I then sewed round the first side of the bias bonding (inside the sleeve). After I had done this I folded the bias bonding over the front of the sleeve then sewed this side in place. I made sure I was extremely slow and controlled on the sewing machine, because it was extremely difficult to sew around the sleeve. Further more I wanted to avoid sewing the sleeve together and to avoid this I constantly checked under neath where I was sewing to make sure the sleeve wasn't catching together. The coloured thread I used to sew the red tartan bias bonding fabric onto the sleeves was black, because I felt that it disguised well within the red tartan material.

once I had sewn in the red tartan sleeve cuffs using bias bonding, I then ironed the waterfall jacket in place. To do this I ironed in waterfall effect folds down the open sides of the jacket. When ironing this in place I made sure it was equally folded on both sides so that the waterfall effect looked professional and accurate.

Over all I was happy with how the bias bonding on the sleeves turned out. However to improve the bias bonding on the sleeves in future I will make sure I am more steady and slow on the sewing machine so that I can achieve more professionally neat results.

My finished waterfall jacket

Once I has finished creating this waterfall jacket I evaluated the final finished garment assessing what I really liked and what I thought I could improve on. I hugely liked the choice of elegant colours which fit together nicely creating an elegantly, smart, classy styled jacket. I also liked the additional feature of the tartan sleeve cuffs, this really brought colour to the jacket making it a unique item of fashion which would create a delicate smart chic look. To improve my Waterfall jacket further I would in future select a a silk like material for the lining so that it created an even more professional classy look.

Bandeau Bodice Garment Sample

I practiced by putting together and constructing a bandeau bodice, to learn the methods of how to construct this garment so that I know how to compose this piece for future reference. I learnt how to place some of the patterns on my chosen fabric, and how to sew these pattern pieces together to create a bandeau bodice.

Cutting out the pattern pieces from my chosen fabric

To start constructing the bandeau bodice I first cut out the paper pattern pieces. once these pattern pieces had been cut out I placed them on my chosen material. For my chosen materials I chose a white fabric for the outside and the lining of the bandeau bodice. I also chose a contrasting black material to have for the front of the bodice for the front pattern piece. When placing these pattern pieces onto my chosen materials I placed them the correct ways using the instructed method. For example the front bandeau bodice piece had to be cut on a fold line, therefore I pinned and secured this pattern piece in place , then cut it out. For this pattern piece I cut it out in the black material and the white material to create a front and a lining. Other pattern pieces that had to be placed and cut out using a specific method was the side front and side back patter pieces. These pieces had to be cut out on reverse. This means that you would pin the pattern and cut aroubd it one side then turn it around and pin and cut round it that side. When cutting out the pattern pieces I had to cut out two front bodices, four side fronts and four side backs to make a front and a lining.

Over all I am pleased with how I cut out all the patterns as I cut them out neatly so that they would be easily pinned and sewn together. I also placed my patterns appropriately onto my chosen materials to save as much material as possible.

Sewing the side front pieces to the front bodice

To start composing the bandeau bodice together I first pinned the two side fronts to the front bodice piece. when pinning these together I had to pull and ease the two materials becaus sides of the pieces were curved. once I had pinned the two side fronts to the front bodice I then secured and sewed them on the sewing machine. I used a black thread for this because the front bodice was black therefore the thread would be more hidden and less easily seen. After I had sewn the two front sides to the front bodice I then repeated this process with the lining.For the lining the material I chose was plain white cotton fabric as I thought this would make a perfect lining for the bandeau bodice.

When sewing the two front sides to the front bodice I made sure that I was slow and controlled on the sewing machine so that I could achieve a nice neat basic seam. I also wanted to be slow on the sewing machine because the pinned side fronts to the front bodice was on a curve, therefore I wanted to maintain control to gain a neat finished look.

Sewing the back sides to the front side pieces

To sew the back sides to the front sides I placed and pinned the two back sides to the front sides, pulling and easing while I pinned because it was along a curve.

Once this had been pinned and secured in place I then went onto sewing and securing it on the sewing machine. When sewing these pieces together I chose to sew using a white thread as the front pieces on the bandeau bodice were white cotton fabric and the lining was also white cotton fabric. once I had sewn the back sides to the front sides I then repeated this process with the lining.

When sewing these pieces together on the I wanted to make sure I was slow and controlled on the sewing machine to achieve a neat basic seam. I also wanted to maintain a slow and controlled speed on the sewing machine for when I went over the pins, so that I wouldn't break the machine needle or break any pins. When sewing these pieces together I used white thread so that it would be less easily seen within the white cotton fabric and look accurate and professional as possible.

Sewing in the lining

To sew the lining into the bandeau bodice i placed the front of the bandeau bodice laying the right way up and I placed the lining ontop of the this facing the wrong way up. I then pinned along the edges making sure I matched up the seams.

I done this so that my bandeau bodice could look as neat and proffesional as possible. Once I had pinned along the top of the bandeau bodice and the two sides, I then went onto securing this in place on the sewing machine. I made sure I didn't sew the bottom of the bandeau bodice because this would be folded in and hemmed later on.

When sewing this in place on the sewing machine I wanted to make sure I was slow and controlled on the sewing machine especially when going over the seams. I waned to achieve a professional neat look. Therefore, when sewing over the seams I made sure I was slow and controlled on the sewing machine to gain a neat finished look. When stitching in the lining I used white thread as I thought this would be the most appropriate colour to use as it would be less easily seen. Therefore, my bandeau bodice would look professional and neat.

Hemming in the bottom of the Bandeau Bodice

To finish of the open bottom of the bandeau bodice I had to hem it in. To hem in the bottom of the bandeau bodice I folded in the materials and pinned and secured this in place.

When hemming the bottom I made sure I matched up the seams so that the bandeau bodice could look as professionally neat as possible. Once I had pinned the hem in place, I then went onto sewing it in on the sewing machine. To sew the hem in on the sewing machine I used white thread. However when I got to the front of the bodice which was black, I changed the thread to black thread so that it wouldn't be seen as easily. After I sewed the hem in place in black thread I then went back to the white thread so that it wouldn't be seen on the white cotton fabric

During this process of sewing the hem in place, I made sure that I was slow and controlled on the sewing machine. I wanted to maintain a slow and controlled speed on the sewing machine especially going over the seams so that I could achieve a consistently straight line. I also wanted to maintain a slow and steady speed so that I wouldn't break the machine needle or any of the pins when sewing over them.

Sewing in the button holes

To finish of the bandeau bodice I made button holes to then eventually thread lace through, to create an elegant lace up bandeau bodice.

To make the button holes I first had to mark out five button holes on each of the edges of my bandeau bodice. To mark these button holes out, I first marked from the middle then made two other marking either side with 5cm between each other. When marking out the button holes I made sure they were marked out accurately so it mirrored and was identical to the other sides button holes. I also made sure I marked the button holes the same amount of distance from the edge of the bandeau bodice. After I had finished marking out the button holes I then went onto sewing the button holes in on the sewing machine. I firstly had to change the foot on the sewing machine to a button hole foot. I then lined the button hole foot up with one of my markings and sewed in the button hole. The process and method of making a button hole on the brother sewing machine was putting the thread tension control between one and zero. I then turned the stitch selector to AC and stitched this so that it went horizontally six times. After I had done this I then made sure my needle was on the left hand side before I turned the stitch selector to B. I then proceeded to sew this until I was satisfied with the length of the button hole. The button hole foot also had markings on it which helped me access when to stop. I stopped when it got to the third marking on the button hole foot. I then turned the stitch selector back to AC and stitched six times horizontally. I then turned the stitch selector to D making sure my needle was on the right hand side. I proceeded to stitch down until I reached the end of the button hole, which I then turned the stitch selector back to AC to then stitch another six times to knot of the button hole. I repeated this process with all the other button holes, making sure I took my time to get it as neat and professional as possible. The markings on the button hole foot helped my button holes to be equal in size.

when sewing the button holes in place on the sewing machine I made sure that I was slow and controlled to reveal a perfectly neat professional stitched button hole. I decided to stitch in my button holes using white thread to match the colour of the bandeau bodice. I really liked how my button holes turned out because they were equally symmetrical and professional to a viewers eye. To improve on the button holes for future reference I will make the length of the button hole longer so that it will be more easily cut and laced up.

Cutting my button holes and lacing them up

After I had made my button holes I then had to gently cut them open so that I could lace them up with ribbon to create a gorgeous lace up bandeau bodice. I first got a sharp stanly craft knife and delicately pieced it through the button holes so that it gently eased away the fabric to reveal a button hole. I repeated this process with all of the button holes making sure I was carful to make it as neat and professional as possible.

When opening up the button holes with a craft stanly knife I wanted to make sure I was delicate and careful so that I didn't cut the actual thread of the button holes open. I made sure I took my time during this process to reaveal neat professional button holes. Over all I was pleased with how the button holes turned out because they looked neat and professional.

After I had finished cutting open the button holes I then went onto lacing the bandeau bodice up with black ribbon. I decided to choose black ribbon as I felt this fit the colours of my bandeau bodice best, complimenting it hugely. When lacing the bandeau bodice up through the button holes I started from the top going under the button hole then laced over the top of the rest of the button holes. This type of lacing was the best way to lace up the bandeau bodice as it gave a classy professional lace up look. When lacing the Bandeau bodice together I did this on a mannequin to make it more easy to lace up and tighten.

After I had laced up the bandeau Bodice I was over all pleased with the final result. The ribbon I selected thoroughly complimented the coloured fabric of the bandeau bodice, and created an elegant unique lace up look.

My finished lace up bandeau bodice

Overall I was thoroughly pleased with how my lace up bandeau bodice turned out. The contrasting black and white fabrics complimented each other hugely. The choice of having the front of the bandaeu bodice in black fabric created an illusion of a more small waist. The gorgeously selected black ribbon created a final elegant touch to the back lace up bandeau bodice. This garment would make a Devine gorgeous going out look for all season. The style of this garment specifically aims at a younger target market in the age bracket between 16-30. The chic addition of black cotton material added just to the bodice area surrounded by the white cotton material, creates an amazing hourglass look which would make a gorgeous item in the fashion industry.

Princess lace up Bodice

I practiced the garment production of a princess bodice, practicing the methods and processes used to construct this piece together. The specific garment pattern pieces for this would piece together to make a gorgeously old historic addition. The particular way this garment is constructed, withholds the historic tudors clothing shape of a Tudor bodice. This specific garment would make a perfect addition to a historical costume.

Cutting out the patterns pieces and placing them onto my chosen fabric

To first start constructing this Tudor styled garment together, I first had to cut out the princess bodice patterns from pattern paper. When doing this process I wanted to make sure that I was precise and accurate to get neat delicate cut outs of the princess bodice paper patterns.

After I had finished cutting out the paper patterns, I then went onto securing and pinning them down onto my chosen fabrics. For my chosen fabrics I selected a grey cotton fabric for the majority off the princess bodice, then a Jacquard, woven, pattern, floral material for the front of the princess bodice. I specifically chose these two materials because they complimented each other thoroughly. The gorgeously printed jacquard material would make a significantly unique centre font piece. The jacquard material also looked very historic and tudor like, therefore I wanted to include it in my princess Tudor bodice. When pinning the paper patterns onto my chosen materials, I made sure I did it correctly following the precise instructed method. One of the paper pattern pieces had to be cut on a fold line, therefore I pinned this piece along a fold line on both of my fabrics (grey cotton fabric and jacquard patterned fabric).

Other paper pattern pieces had to be cut out using the reverse method. Therefore, this instructed method meant I had to cut it out one side, then turn the pattern piece over and cut it out that side. To save time during this process I cut the reverse pattern pieces out with my fabric folded in half, because this made the process allot easier and quicker. After I had pinned down the pattern pieces using an instructed method, I then went onto cutting them out.

During this process I wanted to make sure the I carefully cut out the paper pattens from my chosen materilas so that I could achieve neat accurate cut out patterns. Therefore, when it comes to pinning and sewing the fabric pattern pieces together, they will fit together more comfortably and nicely. I was overall pleased with my cut out fabric pattern pieces, because they were each cut out precisely and neatly with straight cut out edges.

Sewing the front sides of the princess bodice to the front of bodice

After I had cut out my pattern pieces from my chosen materials I then moved onto constructing the front of the princess bodice to the sides of the princess bodice. To begin this process I got the front of the princess bodice from the Jacquard material. I first lay this flat out on a table facing the right way up. I then got the two side front pieces of the princess bodice and pinned these pieces either side.

While doing this I had to pull and ease the material round while pinning in place, due to the front of the princess bodice having curved sides. When pinning this in place I wanted to line the materials up and securley pin them in place so that these pieces of the princess bodice can be neatly sewn in place. Once I had finished pinning the two side fronts to the front of the bodice, I moved onto sewing this in on the sewing machine. After I had securely sewn in the two front sides to the front of the bodice, I repeated this process with the lining. However the front of the bodice for the lining was the grey cotton material instead of jacquard patterned material.

while doing this process I wanted to maintain a slow and steady speed while sewing these pattern pieces together. I used White thread to sew these pattern pieces together as I felt it best fit with my chosen materials. Over all I was really pleased with my quality control on the sewing machine, as I managed to achieve neat basic seams that looked professionally appealing.

Sewing the back sides of the princess bodice to the front sides

Once I had finished sewing in the two front sides to the front bodice, I eventually moved onto sewing the two back sides to the two front sides. For this process I lay down my princess bodice and lay the two back sides ontop of the two front sides, pinning and securing this in place . While pinning, I lined up the materials to make sure that the two materials matched up so I could neatly secure them in place with pins. After both of the back sides had been pinned in place to the front sides, I then went onto sewing this in on the sewing machine. After I had finished sewing in the side back panels to the front side panels, I then repeated this process for the lining, using my grey cotton material.

During this method of constructing the princess bodice I maintained a slow and steady speed on the sewing machine. This made sure that I could produce neat basic seams. I sewed these pieces in using white thread as it matched my material and would less easily be seen by a viewers eye, making it look neat and professional. Overall I was pleased with how the quality control of my stitching tuned out, because I created neat accurate basic seams.

Sewing the back panels of the princess bodice to the back sides

Once I had finished sewing in the two back side panels to the two front side panels, I then moved onto pinning and securing the back panels to the side back panels.

I fristly lay down flat my princess bodice on the table, facing the right way up. I eventually placed the back panels ontop of the the side back panels, securely pinning these in place. Before pinning this in place, I wanted to make sure I lined the two materials up so that when it came to pinning them in place, they will be perfectly matched up and pinned. After I had finished pinning the back panels to the side back panels, I moved onto the sewing machine to securely sew them in place. After I had finished sewing them in on the sewing machine I moved onto the lining, repeating this process.

When sewing these pieces in on the sewing machine I maintain a slow and controlled speed making sure that I could sew these pieces in to the best of my ability. I used white thread again to sew thse pieces together so that the stitching wouldn't be seen as easily, and the garment can look proffesional and appealing. I was overall pleased with the quality control on the sewing machine. My stitching was consistently neat all the way down, creating precise basic seams.

Sewing in the lining

Once I had securely sewn in the back panels to the side back panels, I then started sewing in the lining. To first sew in the lining, I first lay the front of my princess bodice flat on the table.

I then placed the lining over the top of this, so that right sides where together. After I had done this process, I pinned the top of the princess bodice and the two sides, making sure I avoided pinning the open bottom of my princess bodice. When pinning the lining to the front of the princess bodice, I made sure I matched the seams of the lining and the front of the princess bodice up perfectly, so that I can make my princess bodice as professionally accurate as possible. Once I had pinned the lining in place, making sure the seams were accurately matched up along the top of the princes bodice, and the sides of the princess bodice where pinned in place precisely, I then moved onto securing the lining in on the sewing machine.

while doing this process I wanted to make sure I was steady and slow on the sewing machine. This is so i could ahieve a neat finished look to create a princess bodice to the best of my ability. To sew in the lining I used white thread as this best disguised within my chosen grey cotton material, and cream Jacquard material. Over all I was pleased with my quality control when stitching the lining in, because the stitching was equally straight all the way around. I specifically went slow over the seams on the sewing machine when sewing in the lining, so that I could maintain consistent quality control to reveal professional stitching.

Hemming in the bottom and the sleeves of my princess bodice

When I had successfully sewn in the lining, I pulled the princess bodice through to the right side to reveal the neat basic seams. I then started hemming in the bottom of the princess bodice and hemming in the sleevs. To begin the hemming process I first turned in the bottom of the princess bodice and neatly pinned this in place. Before pinning this in place I made sure I matched up the seams so that when it came round to hemming the Botton of the princess bodice in, the seams could be neatly in line and matched up in place. Therefore, this will make my final finished princess bodice as profesionally neat as possible. After I had securely pinned the hem in place, I then moved onto sewing this in on the sewing machine. After I had completely sewn in the hem for the bottom of the princess bodice, I then moved onto hemming the open arm holes. To begin hemming the arm holes, I turned in the arm holes and pinned this in place. I wanted to make sure I turned the arm holes accurately and precisely before pinning the hem in place. After I had pinned both of the arm hole hems in place, I examined and accessed to see if the arm holes were accurately and equally folded in . After I had finished checking to see if the arm holes had precisely been folded in so that it was accurate all the way around, I then went onto sewing this in place on the sewing machine. To sew in the arm hole hems on the sewing machine, I had to pull out the removable plastic compartment on the sewing machine, so that I could pull the arm hole through and securely sew the hem in place.

Over all I was extremely pleased with my quality control when hemming in the bottom and the arm holes of my princess bodice. The hem stitching would be shown on the front of the princess bodice, therefore I wanted to maintain a slow and steady controlled speed on the sewing machine, so that I could achieve neat quality stitching. When sewing over the seams at the bottom of the princess bodice on the sewing machine, I wanted to go extremely slow to make sure I maintained a straight consistent stitched in line. When sewing in the arm hole hems in place, I wanted to maintain neat professional quality control. Therefore, I made sure I specifically went slow on the sewing machine when doing this process. I used white thread when sewing the hems in place because the hems will be shown on the front of my princess bodice. By selecting white thread the stitching will be less easily seen, and my princess bodice will look accurate and professionally done.

Marking out and Sewing in the button holes

To make the button holes I first lay my princess bodice flat on the table and got a piece of tailors chalk to mark out the button holes. I wanted five button holes marked out on each side of the princess bodice.

To mark out the button holes, I first marked out one button hole from the middle of each of the sides of the princess bodice. I then measured out 5cm from either side of this mark and marked down another button hole. After this I marked out another 5cm from this mark, marking out another button hole. I made sure each mark was approximately 1cm away from the side of the princess bodice before marking it out in place. I examined the markings on either side of my princess bodice making sure they were equally symmetrical on either side so that I could achieve proffesional results. After I had finished analysing the princess bodice button hole markings, I then moved onto sewing in the button holes on the sewing machine. To being sewing in the button holes on the sewing machine I first changed the sewing machine foot to a button hole foot. Once the foot had been changed I placed the princess bodice underneath the button hole foot making sure that I lined the button hole up with one of my marks on the sides of the princess bodice. Once the button hole was lined up accurately over one of my marks, I then went onto sewing in the button hole. To Start sewing in the button hole on the brother sewing machine I first turned the hread tension control between one and zero. I then turned the stitch selector to AC and stitched six times horizontally. After I had done this, I made sure that the needle was on the left side before I turned the stitch selector to B and started stitching. While stitching this side of the button hole, I tried to make my button hole long enough for lace to be threaded through. On the button hole foot, there was markings which helped me make out when to stop. I stopped on the forth marking as I felt this was an appropriate length for my button holes. After I had reached the marking, I turned the stitch selector back to AC snd stitched six times. After I had done this process, I then made sure that the needle was on the the right hand side before I turned the stitch selector to D and stitched down. Once I had got to the end of the button hole I then turned the stitch selector back to AC and stitched six times horizontally to knot of the the button hole. After I had finished this process I repeated it with all the other marked out button holes and examined the final result.

I was over all pleased with the quality control of the button holes I made for my princess bodice. The button holes were equally placed on each side of my princess bodice and were symmetrically sewn in place. The length of the button holes were equal in size and looked neat and professional to a viewers eye.

Cutting out the button holes and lacing them up

Once I had finished examining the finished results of the button holes I then started cutting the button holes out gently with a crafting stanly knife. To start this process I got a craft stanly knife and gently cut it through the button holes to gradually wear the material away. I done this process making sure that I didn't cut the actually stitching of the button hole. While doing this process I wanted to take my time so that I could achieve neat and proffesional cut out button holes. Once the process of cutting out all of my princes bodice button holes had been completed, I then moved onto lacing the button holes up together. To start the lacing process, I first selected a grey ribbon to use for the lace of my princess bodice. After I had selected the lace I was going to use, I then started lacing up the back of my princess bodice. The lacing technique I used was coming up through the top two button holes then lacing through over the top of all the rest of the button holes.

I used this lacing technique as I felt it fit my princess bodice nicely and looked aesthetically pleasing. While lacing up my princess bodice, I laced it up on the mannequin so that it would be more easy to lace and I could lace it up to fit the mannequin.

My final finished princess lace up bodice

I was extremely pleased with the final results of my finished princess garment. My quality control throughout the process of this garment production was hugely professional and sleek. The choice of using grey plain cotton and jacquard floral pattern materials created an iconic historically Tudor look, mimicking the styles from Tudor times in a unique modern presentation. The choice of using a jacquard woven material created an historically themed style. The material I chose to go with the woven floral jacquard material complimented each other massively creating an archival chic look.

Shorts Garment sample

Today I practiced how to make a pair of shorts and learnt the method and processes behind this individual garment production. I learnt what pattern pieces are used to make this specific garment, and how to cut them out using a specific method. I then learnt how to construct these cut out fabric pattern pieces together, by sewing them together using a certain process.

Cutting out the pattern pieces and pinning them onto my chosen fabric

To start the process of constructing shorts I first cut out patterns from a pattern paper sheet. I made sure I did this carefully to get neat cut out paper patterns. Once these patterns had been cut out, I then moved onto placing the patterns on my chosen material.

For my chosen material I selected a gorgeous beige tartan fabric. I selected this specific material because I felt that it would make a unique luxurious pair of shorts. The warm tone of the colour beige would create a wonderful winter/autumn styled look which would make a fabulously iconic item in fashion. The specific material I chose would make a chic trendy item of shorts aiming at the target market between the age bracket between 16-30 years. My shorts created out of this fabric will preform an elegant formal and casual look. When placing the paper pattern cut outs on my beige tartan material, I made sure i placed them down in an instructed way. To explain this further, I had to place the patterns down on reverse. This meant that I would place the pattern down one way and pin and cut around it, then place the pattern down the other way and pin and cut around it. To do this process I decided to fold my fabric in half as it saves time and makes the process a lot quicker. Once I had pinned both patterns down on the folded material, I then moved onto cutting out the paper pattern from my chosen materials.

While I was doing this process I wanted to make sure that I was slow and precise when cutting out the paper patterns from my chosen materials. This is because I wanted to get the material patterns pieces as accurate as possible. This is so that when I came to piecing my pattern pieces together, and sewing them in on the sewing machine, it would be far more easy to pin and sew together. Over all I was pleased with my material pattern cut outs, because the edges were all precise and straight.

Sewing the two front crotch areas and the two back crotch areas together

After I had finished cutting out the paper patterns from my chosen materials, I then moved onto sewing the front crotch areas together.

To begin doing this process, I first lay one of the front pattern pieces flat on the table facing up. I then lay the other front pattern piece over the top of this so that it was right sides facing togther. After I had done this I then pinned down the two crotch area sides toegther, making sure I accurately pinned the two font pieces together. When doing this process, I made sure I lined up the two materials so that when I pinned and secured them in place, they could accurately be sewn in. Once I had finished pinning the two crotch areas together making sure I avoided pining the leg hole, I then moved onto sewing this in on the sewing machine. After I had finished sewing this in on the sewing machine, I repeated this method with the two back pieces, pinning and sewing the two crotch areas together.

When doing this process I wanted to make sure I accurately pinned the two crotch areas together for the front and the back. I also wanted to make sure that I was slow and controlled on the sewing machine when sewing in the front and back crotch areas, because the crotch was on a curve. Therefore, I wanted to be slow and precise to create neat straight stitched in basic seams. Overall I was extremely pleased with the quality control of my stitched in crotch areas for the front and back. The stitching was constantly neat all the way around and along the curved edge.

Sewing the front and back crotch areas together

To begin sewing the front crotch area to the back crotch area I first lay out the two front pieces flat on the table with the right side facing up. I then lay the back piece open over the top of this so that right sides were facing together. I made sure I lined the front and the back panels up neatly so that when it came round to pinning them in place, they will be more easily pinned and secured. I started to pin the front and back crotch areas togther, lining up the two materials so they matched together neatly before I pinned and secured it in place. When doing this process I wanted to make sure that I lined up the front crotch area seams to the back crotch area seams. This is so that my finished shorts will have matched up crotch area seams, and my shorts can look professionally done as possible. After I had finished doing this process I went onto securing it in place on the sewing machine.

While sewing in the front and back crotch areas in on the sewing machine, I wanted to make sure that I was slow and controlled, maintaining a steady speed to succeed a neat finished basic seam. I wanted to go occupationally slow over the seams so that my stitching could stay consistently straight and be to the best of my ability. I also wanted to maintain a sensible speed because there was slight curves on the crotch area, and I wanted to control going round these curves when sewing them in place on the sewing machine. Over all, my quality control during this process was successfully neat. The seams matched up perfectly looking proffesional and presentable. I managed to produce good quality seams with consistant straight stitching all the way around the crotch area.

sewing in the waist line

After I had successfully sewn the front and back crotch areas together, I then eventually moved onto sewing in the waist line. To begin sewing in the waist line, I first got an elasticated waist band and measured it around the front of my waist, stretching it gently until it reached the side of my waist.

I then cut this to size for the front of my waist, then cut another piece out the same size for the back of my waist. Once I had cut out the pieces of the elasticated waist band to fit my size, I then moved onto folding in my shorts waist line. To do this process I folded in the waist line of my shorts on the front , making sure that I folded them in the wrong side. I folded them in making sure that there was enough room for the elasticated waist band to slide through. When I was satisfied with the sizing of the folded in waist line I then securely pinned this in place, making sure that it was equally folded in before I securely pinned it down. Once I had pinned the folded waist line in place, making sure the fold was equally folded in all the way across, I then moved onto sewing this in place on the sewing machine. After I had finished sewing this in on the sewing machine I repeated this process for the back of the shorts, making sure the fold was the same size as the front wait line fold, and was equally folded and symmetrical.

When doing his process I wanted to make sure my waist line on my shorts was professionally folded in and was equal on both front panel and back panel to a viewers eye. On the sewing machine I maintained a slow and controlled speed because the stitching of the was will be shown on the front, therfore, I wanted to make it as neat and proffesional as possible. When stitching in the waist line, I decided to use back thread to stitch this in because I felt that it was hidden well within my beige tartan material and would look neat and professional. Over all, I was extremely pleased with my quality control on the waist line. The stitching was consistanly straight on either side of the shorts waist line, and the folded in waist line was equally folded all the way around.

Threading the elasticated waist line through and sewing it in place

To Start this process I firts got one strip of the elasticated waist line band and guided it through the front folded waist line. When doing this process I found it extremely hard to guide the elastic waist band through to the other side, therefore I used a safety pin to help me do this.

The safety pin made the process a lot efficient and faster. When one side of the elastic waist line band had stretched to the side of the folded in waist line, I then securely pinned this in place. This was so that this side of the elastic waist band had been securely fitted in place, so that I could move on to pinning it to the other side. Once I had securely pinned the elastic waist band on either side of the folded in waist line, I then repeated this process for the back of the shorts. After I had securely pinned down both sides of the elastic in the waist line fold, I then pinned the side fronts of the waist line, to the two side backs, making sure they were pinned right sides together. When doing this process I made sure that the elastic was pulled all the way through either end of the folded in waist line before I pinned it in place. This is so that, when it came to sewing it in on the sewing machine, the elastic can be successfully sewn in place. After I had finished pinning the front sides of the waist line to the back sides of the waist line, I then pinned down the two front sides of the shorts to the back sides of the shorts, making sure that I lined up the two materials perfectly so I could sewn them in accurately on the sewing machine. Once everything had successfully been pinned in place, I then securely sewed the elastic waist band in and the shorts sides in on the sewing machine.

When doing this process I made sure I maintained a slow and steady speed on the sewing machine to achieve neat quality seams. When sewing in the elastic, I made sure that it was successfully pulled through on both sides of the folded in waist line, so that I could successfully sew over it and secure it in place. The over all quality control of this process was extreemly controlled. The stitching was precise and accurate which made successfully neat basic seams. To sew this in, I decided to use back thread as it would be less easily seen and look neat and professional.

Hemming the leg holes of the shorts

After I had successfully sewn in the elasticated waist band and the sides of the shorts, I eventually moved onto hemming the open leg holes of my shorts.

To begin this process, I first folded in the open leg holes of the shorts twice, making sure that I was folding it in the wrong side. I then pinned both double folded in leg holes securely, making sure that I had accurately folded the hem in place on both of the leg holes equally; all the way around. After I had finished pinning the hem in place on both leg holes, I then moved onto sewing this in place on the sewing machine. To begin this process I first took out the plastic removable compartment on the sewing machine, so that I was able to slide one of the leg holes through. By removing this compartment, it allows me to achieve a more easily sewn in hem by guiding it around the open leg hole. By doing this process it allows the stitching to be more consistently straight and neat all the way around. Once I slid one of the leg holes through on the sewing machine, I began to securely sew in the hem. I then repeated this process with the other leg hole.

when sewing in the hems of the open leg holes of my shorts, I wnated to maintain a steady slow controlled speed so that I could achieve sleek precise stitched in hems. To sew in the leg hole hems, I decided to use black thread as I felt this best fit with my gorgeous beige chosen tartan material. I decided to use black thread because the stitching on the hem would be seen on the front of my shorts, therefore I wanted to use a colour that was hidden within my chosen material, and would be less easily seen. I was overall pleased with the quality control of the sewn in hems on the leg holes of my shorts. The stitching was consistently straight all the way around which presented a neat professional look for viewers eyes.

Making a cropped boxy T-shirt to make a co-ord set with the elasticated waist band shorts

After analyising and evaluating my finished elasticated waist band shorts garment, I decided to make it into a co-ord by producing a matching boxy T-shirt. To begin making the boxy T-shirt, I used the same paper patterns as the original boxT-shirt I had made. However I wanted to produce a boxy T-shirt that was more cropped and unique, therfore I folded the bottom of the boxy T-shirt patterns in for the front panel and the back panel, making sure I folded them in the same amount so both of the sides matched equally. Once I had done this process, I then proceeded to pin down the paper patterns onto my beige tartan material, using the instructed method and making sure that I placed the patterns saving as much material as possible. Once the paper patterns had successfully been pinned down by using the instructed methods, I then cut out the paper patterns from my chosen material, making sure I was careful and slow, to achieve neat straight cut out edges. Once all the paper patterns had been cut out from my chosen material using the certain instructed methods, I then started constructing the boxy T-shirt together, following the same procceses and methods as the original boxy T-shirt I had produced.

I was over all pleased with the final cropped boxy T-shirt garment I had produced. The over all quality control of this garment was neat and precicely well done. I decided to use black thread again to construct this garment togther, as I felt it best matched within my beige tartan material. The basic seams were extremely well done, and the accurate sewn in sleeves looked professional and presentable. The hem on the bottom of the boxy T-shirt and the sleeves was eaqually folded all the way round, and the stitching was consistantly straight and precise. The bias bonding on the neckline of my cropped boxy T-shirt was also extreemly well done. However, for future improvments, I will sew more close to the edge on the bias bonding on the neckline to make it even more neat and professional.

My final finished cropped boxy T-shirt and elasticated waist band shorts co-ord set